Conceptual Demonstration of Hydrogen Peroxide Based Electrochemical Propulsion with RGA

with Jeongrak Lee, Seonghyeon Kim, Juwon Kim and Hongjae Kang

The development of high-performance green monopropellant-based small thrusters is essential for successful multipurpose space missions. This study experimentally demonstrates a novel electrochemical propulsion system that leverages rotating gliding arc (RGA) plasma to enhance the performance of 88 wt% hydrogen peroxide. This is the first electrochemical propulsion system that utilizes catalytic decomposition gases of hydrogen peroxide directly as plasma-forming gases and an alternating current (AC)-based RGA. The system employs an AC power supply operating at a 20 kHz frequency, combined with a swirler and an anchoring component that ensures geometric stabilization of the arc column. This configuration enabled stable plasma discharge under high-temperature (>200°C) and high-pressure (>2 bar) conditions. The propulsion performance of the plasma reactor was significantly improved by rapidly heating the discharge gases, which were then accelerated to supersonic speeds through a De-Laval nozzle. In the electrochemical operation mode, this process led to consistent enhancements in both chamber pressure and characteristic velocity, achieving approximately 1.4- and 2-fold increases, respectively, compared to the chemical mode (without plasma discharge). The novel propulsion concept can provide a universally applicable solution capable of enhancing the performance of chemical propulsion systems with plasma discharge.

Related Publication:

Jeongrak Lee, Ju Won Kim, Seonghyeon Kim, Anna Lee*, and Hongjae Kang*, "Conceptual demonstration of hydrogen peroxide based electrochemical propulsion with rotating gliding arc," AIAA Journal 63 (7), (2025). [pdf]

Lab-on-PCB for Space Propulsion

with Jeongrak Lee, Seonghyeon Kim, Hanseong Jo and Eunji Lee

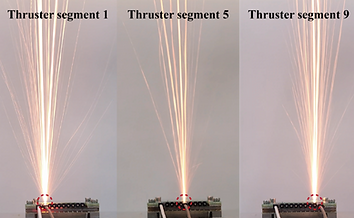

The demand for microthrusters is growing with the increasing utilization of nano/microsatellite platforms in the space industry. Solid propellant microthruster arrays hold great promise for commercial applications due to their lightweight nature and optimization. However, significant challenges exist in scaling up and mass-producing traditional microthrusters, hindering their commercialization. In this paper, we propose a novel concept of a solid propellant micro thruster array and present its fabrication process using lab-on-printed-circuit-board (PCB) technology, along with feasibility studies. All constituent layers of the thruster are fabricated using a commercially available PCB, and the assembly process is conducted using standard PCB surface mount technology. The microthruster array manufactured using this technique exhibits high structural stability due to the robust physical characteristics of its components. Furthermore, the technique can be upscaled and enables cost-effective mass production of components. The ignition characteristics and propulsion performance of the microthruster array are validated through ignition and combustion experiments. A fully functional lab-on-PCB microthruster enables the fundamental integration of electronic control and propulsion systems in a satellite, offering exciting possibilities for future satellite missions.

Related Publications:

Jeongrak Lee+, Hanseong Jo+, Seonghyeon Kim, Eunji Lee, Youngbin Son and Anna Lee*, "Lab-on-PCB for space propulsion: New concept of membraneless micro-ignitor for MEMS solid propellant thruster," Sensors and Actuators: A. Physical 363, 114696 (2023). [pdf]

Jeongrak Lee+, Seonghyeon Kim+, Hanseong Jo, Eunji Lee, and Anna Lee*, "Design and fabrication of a scalable solid-propellant micro-thruster array using Lab-on-PCB technology," Sensors and Actuators: A. Physical 363, 114738 (2023). [pdf]